Application

Tile Applicable Information

In order to get a long life and proper ceramic coating, checking and making the necessary corrections of the surface are very important factors. The required checkings and corrections vary according to whether the surface is a new or an old one. Meanwhile, taking the environmental conditions into consideration is a must.

Environmental Conditions

Because of the seasonal or geographical characteristics, the environmental conditions may change, for example very cold and hot temperatures or being subjected to direct sunlight.

- Applications at low temperatures (lower than +50C) have drawbacks. In order to start with the application, it is necessary to wait until this temperature is reached. This temperature is the lowest one at which the cement based mortars can get the necessary setting.

- Applications at very low temperatures (higher than 350C) have also drawbacks. In this case, the dropping of the temperature into the proper range (between +500c and +350c) is required. Minimally, the surface and the ceramics must be moistened for decreasing the adverse e.ect of the high temperature.

- For the applications under wind and direct sunlight, efficiency diminishes due to decrease of working time. If the applications is necessary, either dampen the surface or for a better result use CONSET PRIMER. In addition, application of the mortar to the surface with shorter periods or buttering method is recommended.

Surface Examination and Surface Preparation

New Surface: The surface (like concrete, plaster and screed) should be strong and of 3-4 week cured. Residues like shuttering lupe that may affect adhesion should be removed and irregular, uneven areas should be flattened with THIXOPIC repair mortar, correct floor disorders with CONSET 45 T leveling mortar.

Old Surfaces: The strength of the surfaces should be carefully examined without considering how well the holding power of the new adhesive is. The concrete surface must be checked in certain intervals with a hammer, nail or chisel and it is easy the present concrete must be scraped out until the strong surface is reached, any cracks or holes has to be filled with THIXOTROPIC and flattened.

When making the surface correction at the uneven sections of the floor, correct the local disorders with THIXOTROPIC repairing mortar, and all surface disorders with CONSET 45 T levelling mortar. The paint, mortar, oil and dirt on the surface should completely be removed because they have negative effects on adhesion.

- Absorbent surfaces: The surfaces with high water absorbency (plaster block, plaster plate, aerated concrete, wood etc.) must be primed with CONSET PRIMER or CONSET SMOOTH SURFACE PRIMER for preventing quick evaporation of the water in the mortar that leads weak adhesion. For treatment of anhydride surfaces should be used.

- Ceramic coated surfaces: In case ceramic re-coated on ceramic coated surface, check present coating with a hammer first. If there is weak, hardly stuck ceramics either re-.x them or remove them and .ll the gaps with CONSET repairing mortars. for this application, the selection of the adhesive mortar is important.

- Painted Surfaces: Before any application the painted surface must be checked .rst. If there are loose and swollen areas, then they should be scrapped out. In order to increase the holding powder, scoring the surface is recommended.

- Please carefully examine the sections special applications and the product lea.ets.

Adhesion Method

The three international methods are used for the applications of the adhesive mortars. The main purpose to be considered here is to cover the backside of the coating plate with the mortar completely, leaving no gaps. The notched trowel type to be used in these applications is a complementary factor.

Combing Method

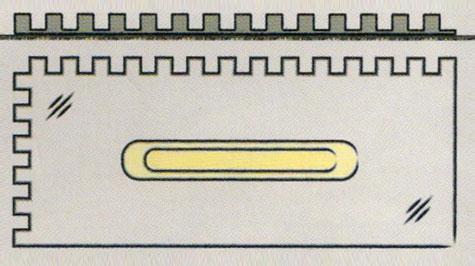

This is a most widely used method applied in fixing of the small and medium sized coating materials in fined bed mortars.

The adhesive mortar is spread onto the surface with a plain hand trowel applying a sweet force, and then is spread with notched trowel with proper size teeth with 450-600 C handling angle.

After these operations, the coating materials is fixed onto the mortar bed applying force on. Additionally the coating materials is fixed with the help of a rubber or wooden hammer in order to increase the holding power and spread of the mortar under the tile then levelled

Combined Method

This method is the one in medium bed mortars and should be applied in sticking of the big size coating materials and the surfaces where heavy pedestrian and load traffic exist, in cold climates and for the outer surface applications. The adhesive mortar is applied onto the surface ten pulled with a notched trowel like combing material and applied onto the backside of the coating material as a thin layer like buttering method. After these operations the coating material is fixed onto the mortar bed applying force on.

Additionally the coating material is fixed with the help of a rubber or wooden hammer in order to increase the holding power and spread of the mortar under the tile then levelled.

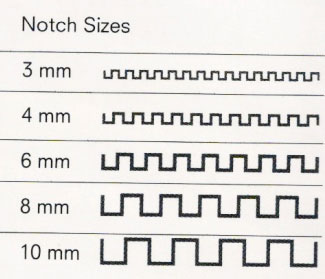

Notch Trowel

Notch Size Table