Conextra 65

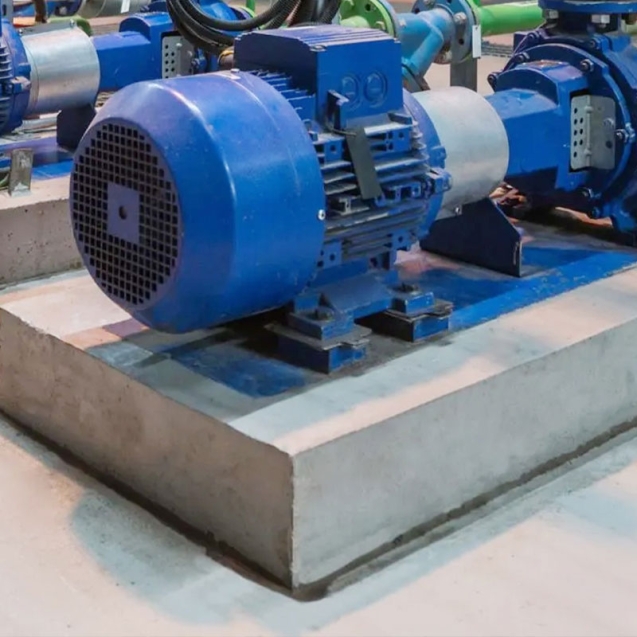

Non-shrink, free flow, ultra high strength cementitious grout for dynamic load

Conextra – 65 is supplied as a ready to use dry powder. The addition of a controlled amount of clean water produces a free flowing, non-shrink grout for gap thickness up to 100mm.

Conextra – 65 is a blend of Portland cement, graded fillers and chemical additives which impart controlled expansion in the plastic state whilst minimising water demand. The low water demand ensures high early strength. The graded fillers are designed to assist uniform mixing and produce a consistent grout.

- Gaseous expansion system compensates for shrinkage and settlement in the plastic state.

- No metallic iron content to cause staining.

- Pre-packed material overcomes onsite batching variations.

- Develops high early strength without the use of chlorides.

- High ultimates strength ensure the durability of the hardened grout.

- Free flow ensures high level of contact with load bearing area.

Description

Conextra – 65 is used for precision grouting where it is essential to withstand state and dynamic loads. Typical applications would be the grouting of base plates of turbines, compressors, boiler feed pumps etc. It can also be used for anchoring a wide range of fixings. These include masts, anchore bolts and fence posts.

Consumption

2150 kg./m3

Packing

25 kg. bag

Technical Information

An experienced technical advisory team is available to give technical service on request.

PROPERTIES

| Compressive strength: (BS 1881 – Part 116: 1983) | ||

| Compressive strength (Nmm2) | ||

| Age (days) | Consistency | |

| Flowable (W/P 0.18) | Pourable (W/P 0.165) | |

| 1 | 22 | 25 |

| 3 | 40 | 48 |

| 7 | 50 | 60 |

| 28 | 60 | 65 |

| Compressive strength with addition of aggregates | |||

| Compressive strength (Nmm2) W/P 0.18 | |||

| Age (days) | % of aggregates (IS 516 – 1959) | ||

| 50% | 75% | 100% | |

| 1 | 25 | 26 | 30 |

| 3 | 45 | 47 | 40 |

| 7 | 55 | 57 | 58 |

| 28 | 65 | 68 | 69 |

Flexural strength (BS 4551, 1998)

| Age (days) | Flexural strength (Nmm2) |

| W/P 0.18 | |

| 1 | 2 |

| 3 | 5 |

| 7 | 7 |

| 28 | 9 |

| Tensile strength | 3.0 Nmm2 @ 28 days |

| (W/P – 0.18) | |

| Time for Expansion | Start: 20 minutes |

| (After mixing) | Finish: 120 minutes |

| Freshwet density |

- Place 80% of the water required in a concrete mixer [100% in case of a grout mixer].

- Slowly add the required amount of CONEXTRA – 65 while continuously strring for 1 minute. Add balance quantity of water (20%) and mix for 3 to 5 minutes. This will provide a smooth even consistency of grout The mixd grout must be placed imediately and grouting must be continued till the cavity is filled.

- All contaminated surfaces must be cleaned thoroughly by chemical or mechanical methods.

- All bolt pockets and under bases must be free from dust, laitance and of sound substrate. If needed, substrate with water to allow for full absorption for atleast 24 hours. Just before the grouting is to commence, all water must be removed completely leaving the surface only damp.

How to Use

MIXING

Mechanical mixing using a grout mixer or freefall concrete mixer is recommended. No hand mixing is permitted.

SURFACE PREPARATION:

BOLT POCKETS:

Depending on the size of the boll pockets. 50-100% cleaned 10mm sound aggregates by weight of grout consumption may be incorporated to economise on grout and also to keep the heat of hydration low. When the thickness exceeds 100mm-150mm our technical department may be contacted for advise. There must be atleast 12 hours gap between bolt pocket and under base plate grouting sequence.

UNDERBASE PLATE:

Leak proof strong formwork must be provided to withstand operational stresses while grouting and all edges must be sealed with CONEXTRA – 65 of trowelling consistency to arrest the grout from flowing out of formwork. The sealed edgesmust be strong enough to resist fluid grout (atleast 1-2 hours after sealing). Hydrostatic head 150-250mm must be provided to enable the free flowing of grout under base plate. Grouting must be continuous until the cavity is completely filled to the desired level. The exposed areas must be kept to a minimum. 100-150mm on the grouting side and 50mm on the opposite side. All exposed areas must be restricted by covering with wooden planks or polythene sheets with sand sprinkled on top of the avoid cracks on the grouted surface.