Home » Products » Conset Tilemate TG (F)

Conset Tilemate TG (F)

Flexible, Rustic Grouting Mortar (6-20 mm)

High preformance (high resistance to abrasion and reduced water absorption), cementitious, flexible grout for 6 to 20 mm joints.

Description

Fields of Application

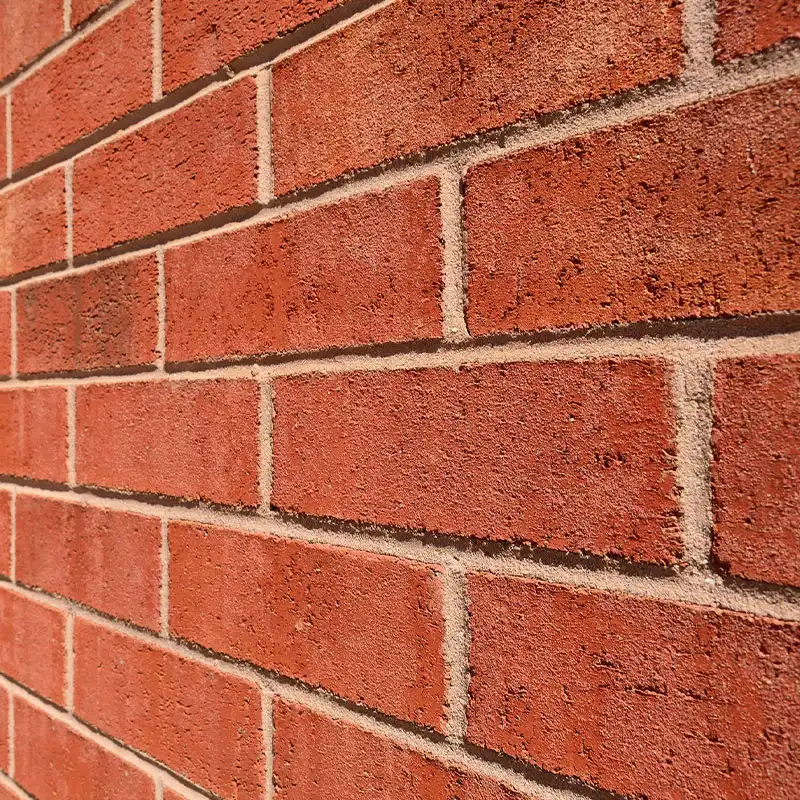

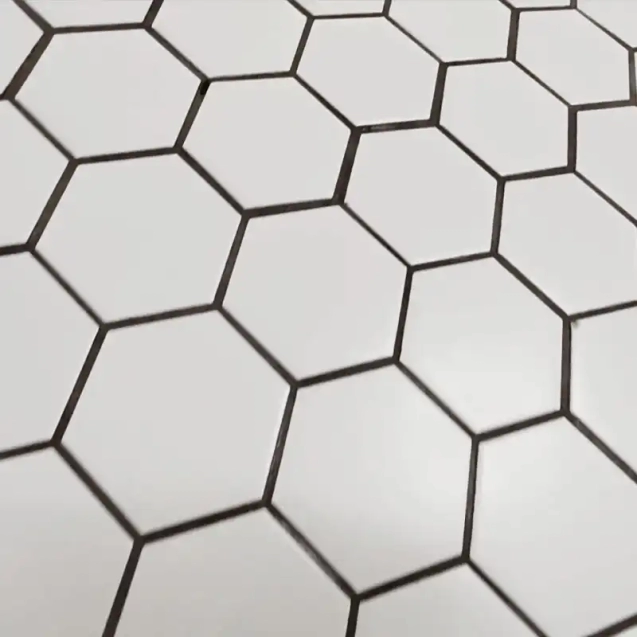

• Grouting interior and exterior floor and wall in all types and sizes of ceramic tiles, granite, cotto, clinker, glass mosaics, marble, natural stone, antiqued marble 6-20 mm joints.

• Grouting wet places like swimming pools, water tanks.

• Grouting places where sudden temparature changes and heavy traffic exist like facades, terraces, over floor heating installations, warehouses.

Properties

• Approved to be used in contact with water intended for human consumption.

• High flexibility.

• Good compressive and flexural strength and good resistance to freeze/thaw cycles.

• Low water absorption.

• A rustic final surface.

• Very good abrasion resistance.

• Low shrinkage, therefore absence of cracks and fissures.

• Ultra-violet and atmosphere resistant 12 different colours.

Warnings

• Since contains cement, irritating to eyes, respiratory system and skin. For further information refre to safety data sheet.

• Grout colors may show difference from original because of the printing method used in this color card. The absorption of tile, water content of grout and climatic conditions may effect color shades.

Storage

Storag in dry medium. Do not stack more than 20 bags on top of each other.

Packaging

10 kg multi-ply paper bags.

Technical Information

| Technical Properties | (at 230 C) |

| General Data | |

| Appearance | White and coloured powder |

| Shelf Life | 12 months when stored in the original sealed packing in dry place. |

| Application Data | |

| Application Temperature Range | (+50C)-(+350C) |

| Pot life | 1 hours |

| Mixing Ratio | 4-4.4 liters water/ 20 kg powder |

| Set to Light Traffic | 1 Day |

| Consumption | See Consumption Table depending on width of the joints and dimensions of the tile. |

| Performance Data | |

| Flexural Strength (EN 12808-3) | ≥2.5 N/mm2 |

| Compressive Strength (after 28 days) (EN 12808-3) | ≥15 N/mm2 |

| Flexural Strength (after freeze/thaw cycles)(EN 12808-3) | ≥2.5 N/mm2 |

| Compressive Strength (after freeze/thaw cycles)(EN 12808-3) | ≥15 N/mm2 |

| Abrasion Resistance (EN 12808-2) | ≥1000 N/mm2 |

| Shrinkage (EN 12808-4) | ≥3 mm/m |

| Water Absorption (after 30 min / 4 hours) (EN 12808-5) | ≥2g /≥5g |

| Service Temperature Range (after final cure) | (-300 C)-(+800C) |

How to Use

• Before grouting, wait until the adhesive has completly set.

• The joints must be clean, free of dust and raked back to at least 2/3 of the tile thickness.

• It is advisable to use Surface Cleaner & Protector before application of Tilemate TG (F) on rough or porous tiles and stones for easy cleaning.

• Wet the joints with clean water when using very porous ceramic tiles in high temperatures and in the presence of wind.

• Pour 20 kg of Tilemate TG (F) in to 4-4.4 liters of clean water slowly and mix to obtain a homogeneous paste free from lumps. A low speed mixer is recommended to mix. Amount of water should be precisely measured. Do not add any additive which is not mentioned in the instructions for the application. Excess water can cause cracking, low abrasion resistance and colour defects.

• Allow to stand for 5-10 minutes to mature. After 1-2 minutes remixing, the paste is ready for application.

• Fill the joints completely with Tilemate TG (F) using the appropriate rubber trowel, making sure the joints are completely compacted. Remove excess Tilemate TG (F) from the surface moving the float diagonally across joints.

• When the mixture loses its plasticity and becomes matt, usually after 10-20 minutes, clean the surface with a damp sponge working diagonally to the joints. If cleaning is carried out when the mixture is still plastic, the grout may be dragged from the joint leading to colour variations.

• Any residue left can be cleaned from the surface with a clean dry cloth.

• If the surface of walls and floors are still contaminated with Tilemate TG (F) use Cement Remover to Clean, at least 10 days after grouting the joints.

• Dispose mortars of which pot life is expired. Clean tools and containers with plenty of water before Tilemate TG (F) hardens.

• When applying Tilemate TG (F) in extremely hot, dry or windly climates, it is recommended to wet the joints after several hours to improve the final performance.